About A.G. Stacker Inc.

Committed to Innovation. Committed to You.

Mission & Values

A.G. Stacker has been a leader and innovator in the custom manufacturing industry since 1996.

We Build to Suit

We Build to Last

We Stand Behind Our Systems

We're Always Innovating

We have 30+ patents on our existing technology and have expanded our offerings to include digital twin technology for our most popular equipment, an A.G. Mobile App, and created the Digital Innovations Lab at our facility in Weyers Cave, VA.

The History of A.G. Stacker

Founded in 1996 by Clarence and Helen Allen,

A.G. was created with a commitment to innovation that remains alive to this day.

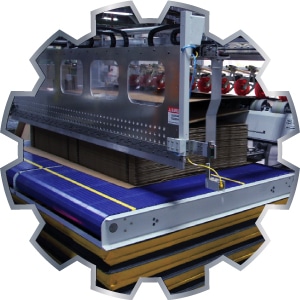

A.G. Stacker began as a full-service rigging company for custom plant moves, installations and redesigns. After years in the corrugated industry, the Allens gravitated towards innovation in rotary die cutter stackers and were inspired to pursue new, patent-seeking designs to improve the productivity, safety and longevity of this sector. With the first piece of original A.G. equipment released in 2000, the founders began selling and retrofitting stackers with A.G. equipment and upgrades. In 2007, the XRI™ Stacker came to market and has served as a proven stacker design that A.G. continues to build on to this day.

In 2008, A.G. received its first, of now 30+, patents and currently has multiple patents pending with the USPTO. As the spirit of innovation continued to increase throughout the years, so did A.G.’s product offerings, with the addition of the X12™ Pitless Lift Conveyor and the Bundle Conveyor System in 2012. In 2016, the G3™ Stacker entered the market, building on the X12™ platform and adding divert and separate, sample quality rejection and servo-driven tamper patented technologies to A.G.’s equipment lines.

With the appointment of Joe Wunder as President in 2017, A.G. shifted their innovation internally and put an emphasis on people, processes and technology. This sparked a full digital transformation whereby all A.G.’s operations, engineering, service and production are connected and available, any time and any where. By 2020, A.G. had developed multiple digital technologies, including augmented reality service options, a mobile application, a virtual reality factory environment, digital twin technologies and other internal processes. This set the stage for the new eSERIES™ equipment line – A.G.’s fully electric, fully integrated systems including the eBREAK™ Bundle Breaker and eZF™ Load Former.

We do more than just assemble a machine. With multiple patents issued, we embrace focused, concise design to develop the equipment, technology and service options that meet the unique needs of corrugated converters, for years to come. We are #MadeInAmerica – cutting steel, machining parts, and building equipment from the ground up in the Shenandoah Valley of Virginia. We provide customer service with the intent of not only fixing a problem, but also building a relationship.

Now that you know our history, we would love to hear yours.

Give us a call and let’s innovate together.