The XRI™ Corrugated Stacker

The XRI™ Corrugated Stacker offers an innovative design and heavy duty construction. Known by Boxmakers as the stacker investment that will last decades.

Control Board

Remove Scrap

Stack Neatly

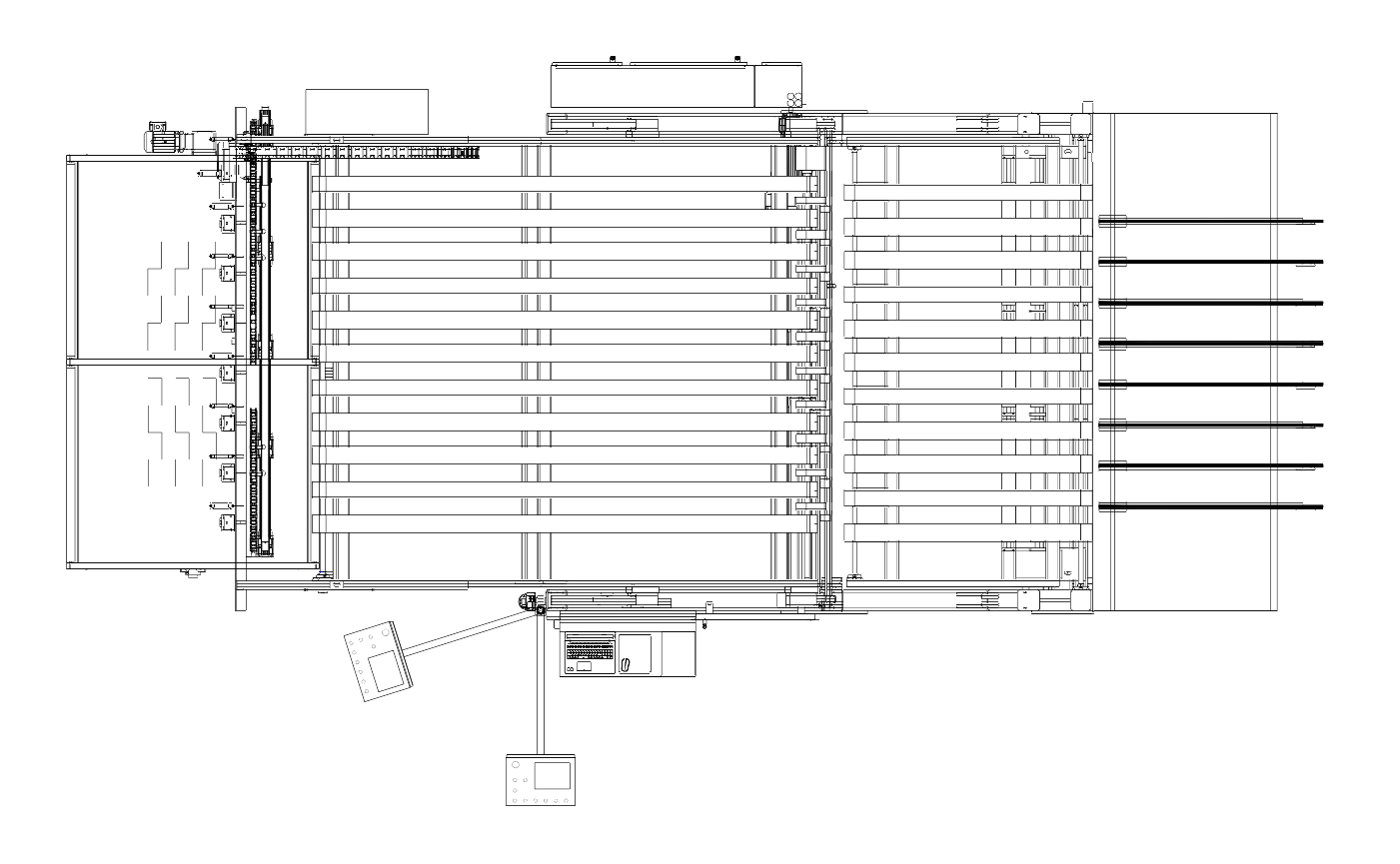

XRI™ Stacker Sizes

The XRI™ stacker is a versatile corrugated stacker machine available in the following sizes as well as customized and jumbo sizes:

115″ 125″ 135″

ENGINEERED INNOVATION

COMMITTED TO INNOVATION

With multiple patent and patent pending innovations, our corrugated stacker systems are engineered to increase safety, productivity, and connectivity for converters nationwide.

Intelligent Safety System

Accurack

COMMITTED TO SAFETY

COMMITTED TO SAFETY

At A.G. we put safety first when it comes to engineering and designing our stackers. The XRI™ Corrugated Stacker includes the following safety measures

No Pits

Ergonomic Designs

Voltage Separation

UL 508A

Automatic Set Up

Hard Guarding

Panel Access System

Fully Integrated Safety Features

DIGITAL TECHNOLOGY

GO AG™ DIGITAL APP ENABLED

A.G. Stacker has not only invested in a Digital APP, GO AG™, but features of the XRI™ Corrugated Stacker are also DUO™ digital twin enabled! Available as a service upgrade, GO AG™ allows converters to take advantage of

Parts Manuals & FAQs

In-APP Service & Parts Requests

3D AR Equipment Models

XRI™ Stacker Standard Features

- Layboy Section

- Accuset Layboy Arms

- Zero Crush Snubbing Wheels

- Solid Aluminum Backstop

- Accurack

- Powered Rollout

- Intuitive HMI

- Side Catchers

- Deck Lock Out System

- Intelligent Safety System

- Remote Diagnostic System

- Proportional Valve Hydraulics

- Ergonomic Operator Station

Understanding A.G.’s Corrugated Stackers

Features |

G3™ Stacker |

XRI™ Stacker |

| Mobile APP & Digital Twin Enabled | X | X |

| 13,500+ KPH | X | X |

| 4-Out Capability | X | X |

| Layboy Section | High Performance Layboy | Original Layboy Section |

| Accuset Layboy Arms | X | X |

| Accurack (P) | X | X |

| Powered Rollout | X | X |

| Intuitive HMI | X | X |

| Side Catchers | X | X |

| Snubbing Wheels | Carriage Style Snubbing Wheels | Zero Crush Snubbing Wheel |

| Backstop | Ventilated Vision Backstop | Solid Aluminum Backstop |

| Deck Lock Out System | X | X |

| Intelligent Safety System (P) | X | X |

| Remote Diagnostic System | X | X |

| Proportional Hydraulic Controls | X | X |

| Ergonomic Operator Station | X | X |

| Air-Operated Deck Snubbing Wheel Lift System | X | |

| Tampers & Dividers | X | |

| Accumulator Back Tamping | X | |

| Pivoting Hopper Guides | X | |

| Scrap Release Technology | X | |

| Order Memory System | X | |

| Flexi Deck | X |

Innovation comes Standard

Standard features of A.G’s Corrugated Stacker

*(P) indicates patented systems*

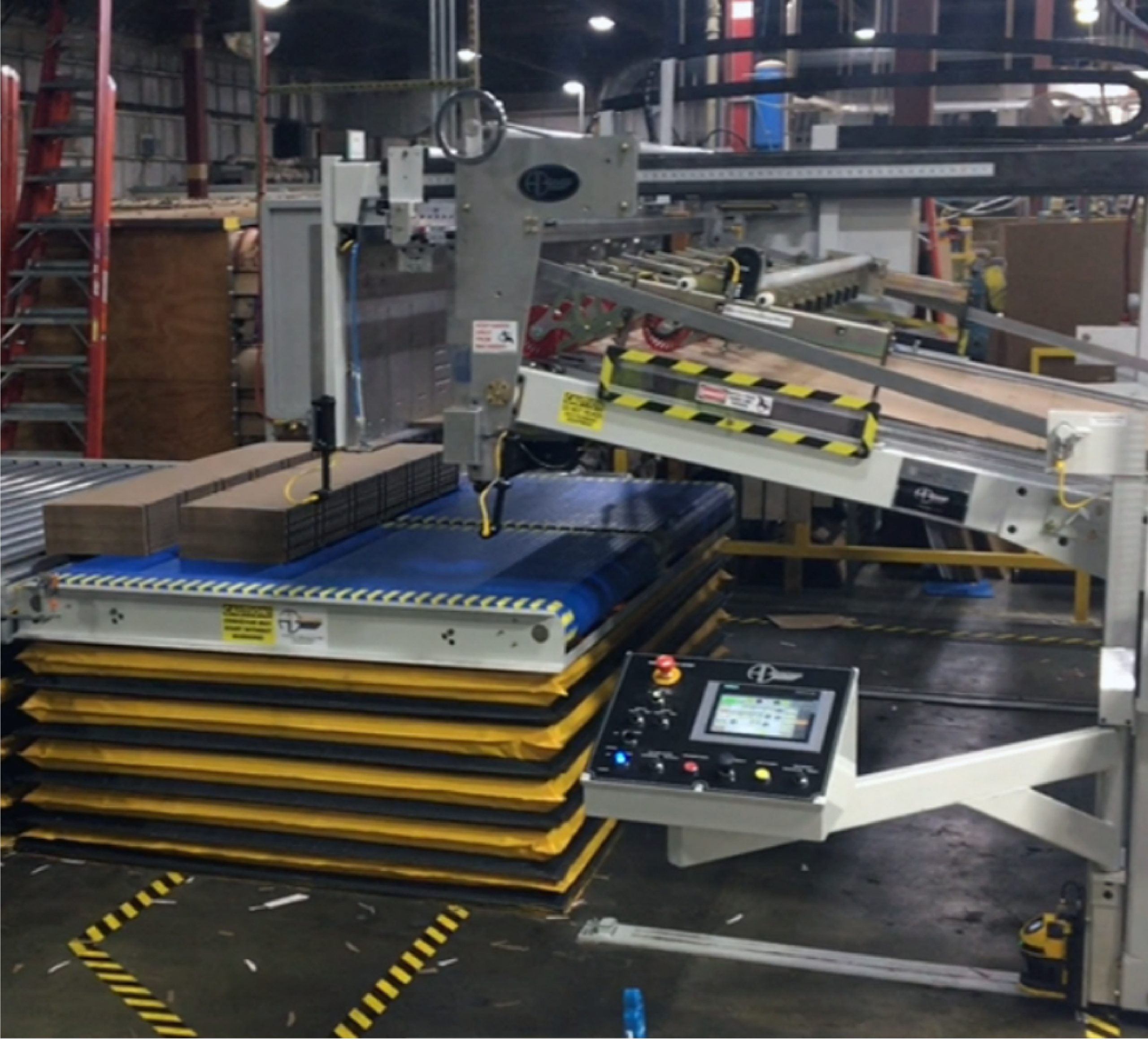

Operation control station

Ergonomically mounted color touch screen is intuitive and easy to learn with no cumbersome boom. Memory system available.

Intelligent safety system iss (P)

State of the art system that consistently scans, detects, records, and alerts personnel in or near safety zones to ensure operator safety.

ACCURACK ACCUMULATOR RACK (P)

Single motor servo driven movement with smooth electric start and stop reducing the need for maintenance.

DECK LOCK OUT SYSTEM

Allows mechanical locking of the main deck, while the deck is raised, to allow safe access for cleaning and maintenance.

Accuset Layboy Arm Adjustment

Set all layboy arms to the same setting on each dial for fast & accurate setup!

TAMPERS

Pneumatic or electric driven to aid incoming boards onto stack. Multiple modes of preference available.

proportional hydraulic control

Regulate smooth vertical transitions of the stacker.

Solid Reinforced Backstop

Reinforce backstop to prevent flex for consistent stacks and improved performance.

REMOTE DIAGNOSTIC SYSTEM

Allows A.G. technicians to monitor and run diagnose issues remotely.

XRI Corrugated Stacker Optional Features

*(P) indicates patented systems | (PP) indicated patent pending systems*

SRX™ Scrap Release Layboy (PP)

High Velocity Scrap Blowers (4×5 HP)

New Engineered Air Knife Design, with Varible Speed Control

New Scrap Release Layboy Arm Design

Requires HPLX

Divert & Separate Section (DSS)

Drag-and-drop screen allows for quick adjustment of diverting section for multi-out while line runs or to automate machine setup

SEMI-AUTOMATIC PALLET INSERTER (EPX™)

Manually Feed Roller Conveyor with Roll In/Roll Out Capability

Operator Side of Stacker Shuttle Cart

12″ Top of Roller

Shuttle Cart with 15′-0″ of Travel

SERVO-DRIVEN TAMPERS | ETAMP (P)

Complete backstop and tamper set up by pushing a button or adjust from the HMI as the line runs.

flexi-deck (P)

This flexible transfer desk sits between the layboy and main deck to ensure blanks transfer onto a level, gap-free surface.

PIvoting Hopper Guides

Pivots easily to meet irregularly-shaped sheets. Can be retrofitted to existing stacker.

air operated deck lift

Raises the deck snubbing wheels vertically to make clearing a job fast, safe, and easy.

SAMPLE QUALITY REJECTION

SYSTEM (P)

As simple as the push of a button, the SQR operates at full speed with manual or automatic capability for rejection. Receive board for quality samples or print quality checks, while keeping operators safe, running at full production.

FEATURES & BENEFITS

Over 12,000+ KPH

New Log Every 8 Seconds

Bundle Conveyor System

HIGH SPEED HOPPER EJECTOR | HSHE (P)

Paired with the bundle conveying system, the HSHE has the look and feel of a normal backstop and allows for the fastest cycle time when discharging or moving bundles.

FEATURES & BENEFITS

Rotating Dampening Rollers

Additional Lay Boy Arms

Scrap Conveyor Lead Edge Guides

Laser Line (P)

Accu-Nip

Dual Air Blades

Layboy Touch Screen

Let's Get Started

Find out how an A.G. XRI™ Corrugated Stacker can improve your workflow.