Corrugated Technology Solutions

A.G. has been prepping the way for a complete digital transformation of A.G. Systems, whereby all operations, engineering, service and production are connected and available, any where at any time.

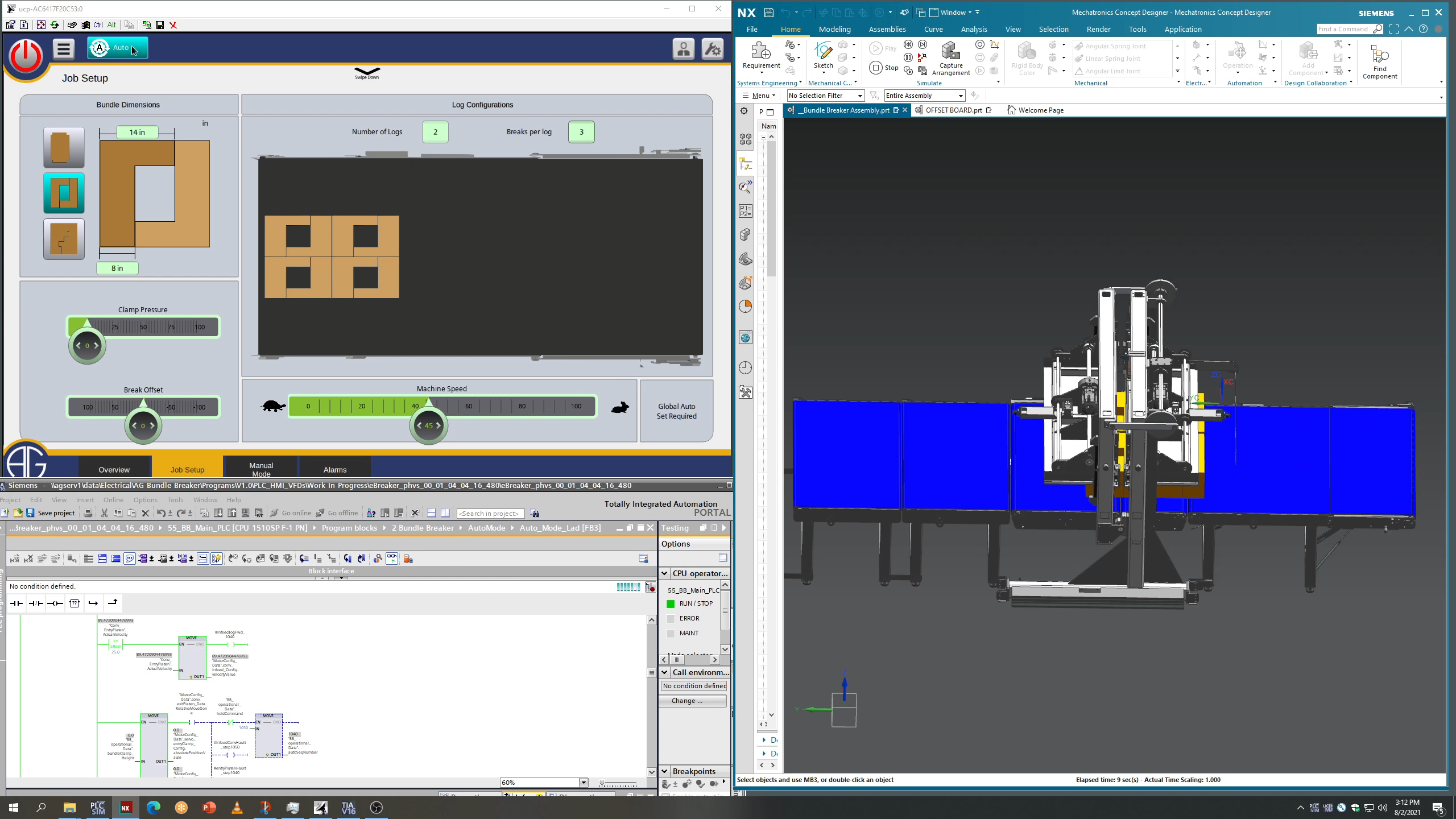

DUO™ Digital Twin Technology

GO AG™ Mobile APP

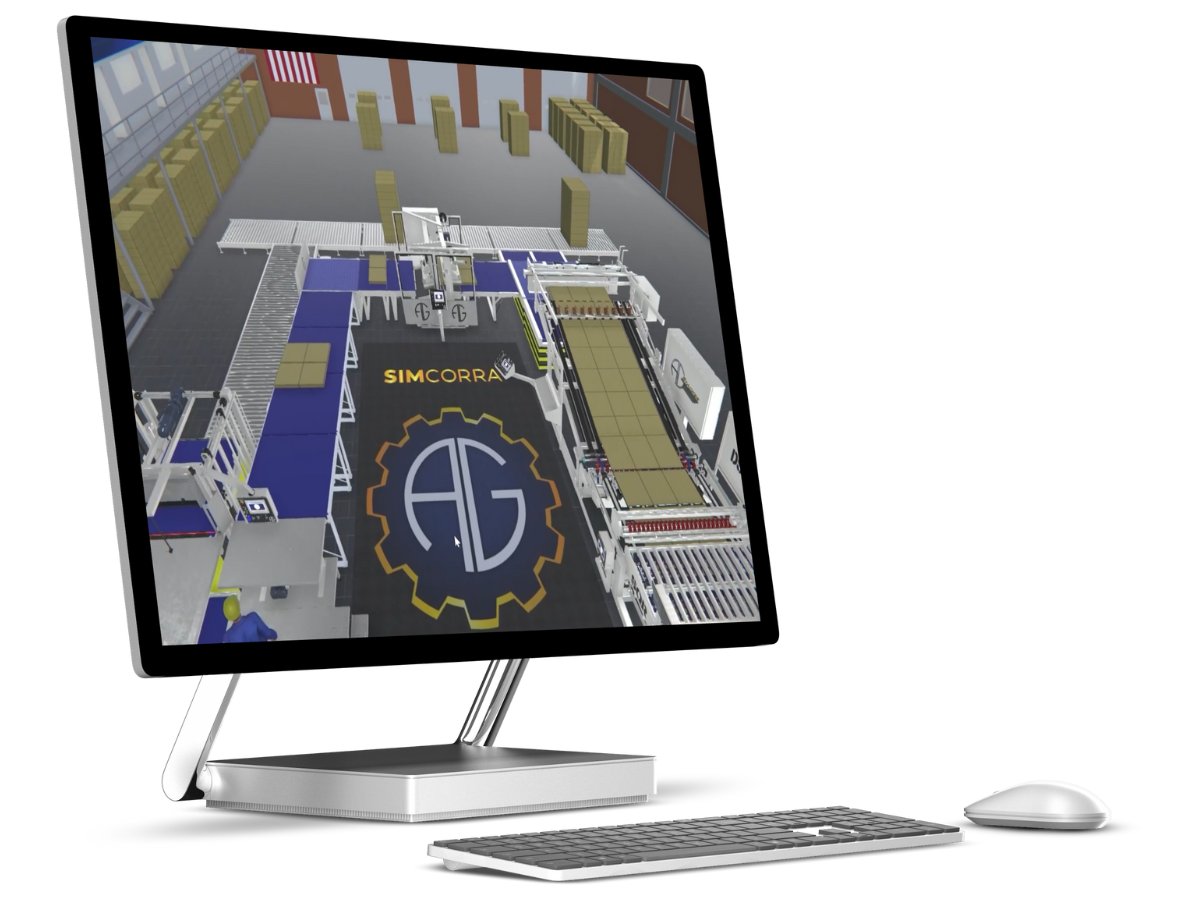

SIMCORRA™ Custom Factory Simulations

Virtual Reality

Let's Get Started

Find out how A.G.’s corrugated technology can keep you connected and productive.