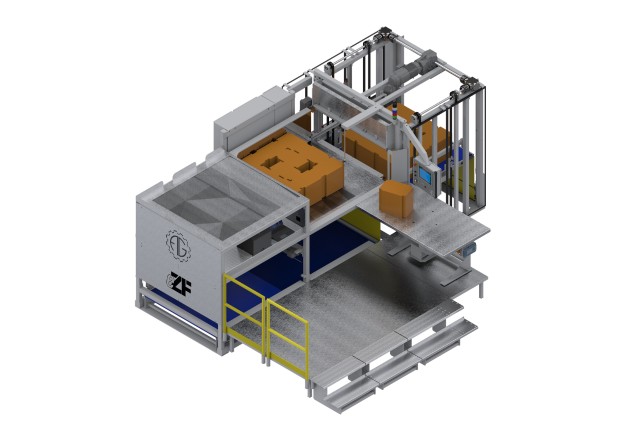

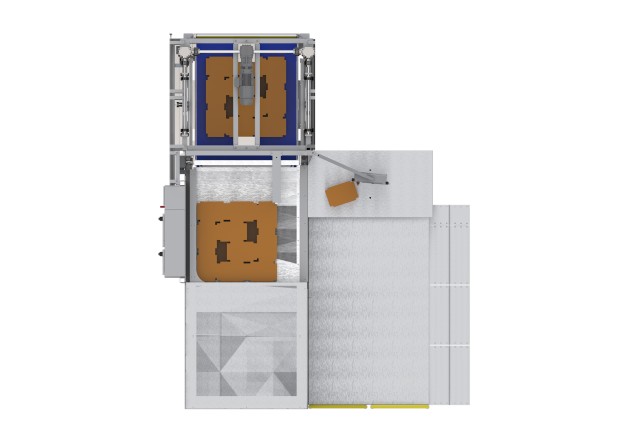

eZF™ Load Former

eZF™ Load Former

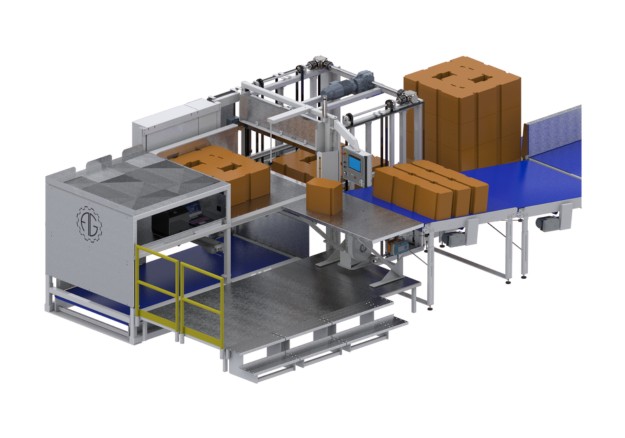

This patented and patent-pending load former system semi-automatically builds bundle loads up to 96″, without pits.

No Pits!

Auto Cycle Modes

Order Recipe Recall System

Multi-Patented & Patent-Pending Technology

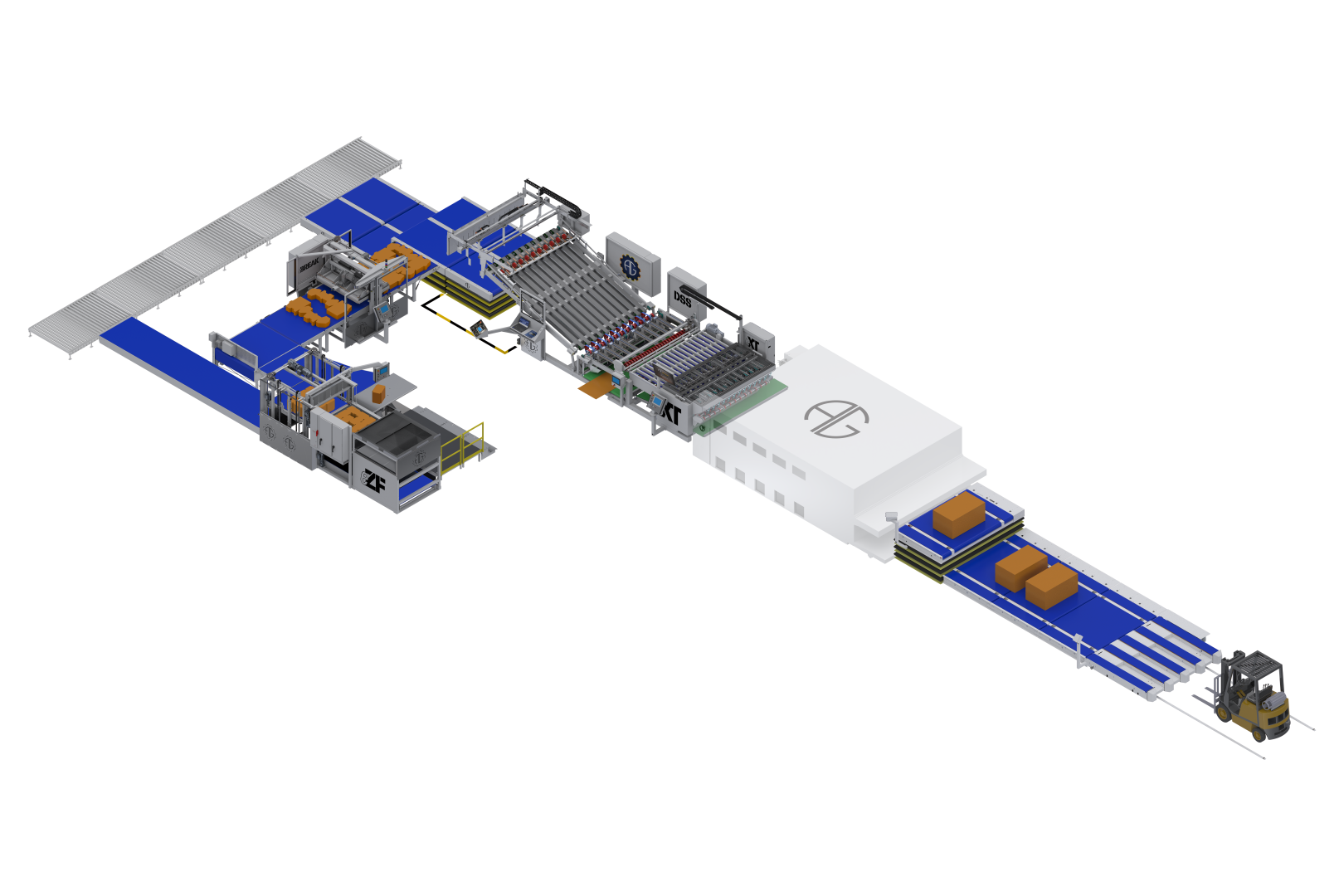

Fully integrated with your Stacker and Bundle Breaker, the eZF™ Load Former is part of the NEW eSERIES™ equipment line, designed to embrace digital transformation in your facility.

No Pits!

Auto Cycle Modes

Loads up to 96" Height

Order Recipe Recall System

Fast Cycle & Set Up Times

Modular Design

Integrated Safety Features

Fully Integrated to the Stacker, Bundle Conveyor System & Bundle Breaker

eSERIES™ EQUIPMENT

eSERIES™ EQUIPMENT LINE

Systems in the NEW eSERIES™ product lines are fully electric, fully integrated high speed systems without pits, pneumatics or hydraulics. The eSERIES™ innovations prepare the way for a complete digital transformation of A.G. systems.

Fully Electric

Fully Integrated

No Pits, Hydraulics or Pneumatics

Digital Twin Enabled

LOAD FORMER SAFETY

INTEGRATED SAFETY FEATURES

When building loads up to 96″ high, it is important to protect your operators from strain and injury. A.G. has engineered multiple integrated safety features to reduce risk in the load forming process:

Voltage Separation

Hard Guarding

Auto Lock System

Integrated to A.G. Line

DIGITAL TECHNOLOGY

GO AG™ DITGITAL APP ENABLED

A.G. Stacker has invested in a digital app, GO AG™, available as a service upgrade, for all A.G. customers. (Click here to learn more about A.G. Digital Technologies.) Using GO AG™, converters can take advantage of:

Parts Manuals & FAQs

In-APP Service & Parts Requests

3D AR Equipment Models

Improve End of Line Efficiency

WITH THE

NEW eZF™ Load Former

Let's Get Started

Find out how an A.G. Load Former can improve your productivity.