Innovative Corrugated Machinery

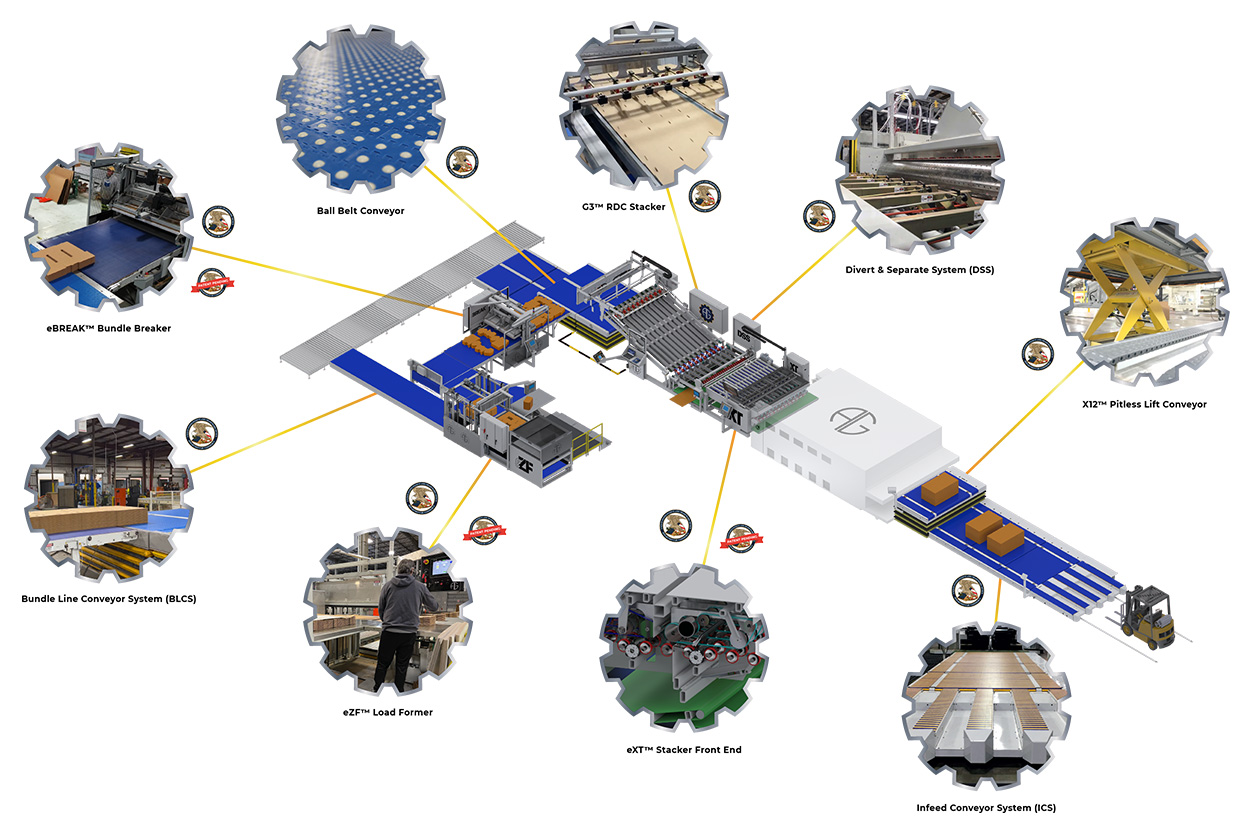

A Full Line of Converting Solutions & Technology

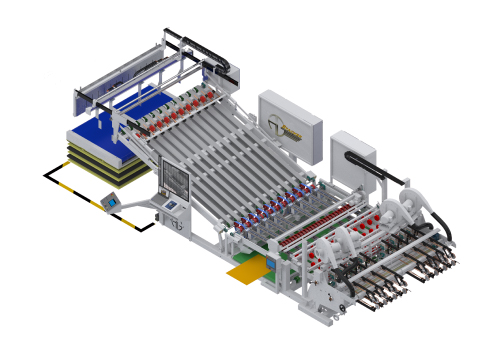

The eSERIES corrugated machinery prepares the way for a complete digital transformation of A.G. systems.

Systems in the NEW eSERIES™ product lines are fully electric, fully integrated high speed systems without pits, pneumatics or hydraulics.

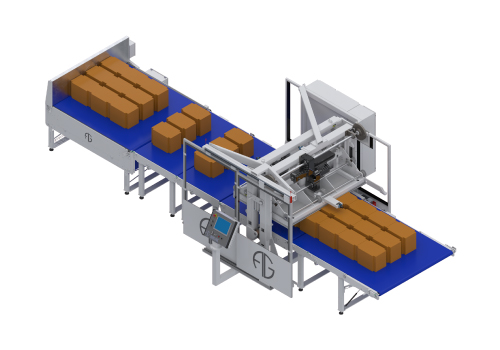

eBREAK™ Bundle BreakerCapable of a variety of bundle configurations and heights, the patent-pending eBREAK™ Bundle Breaker is a dynamic solution to improve end of line efficiency.

|

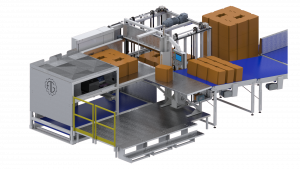

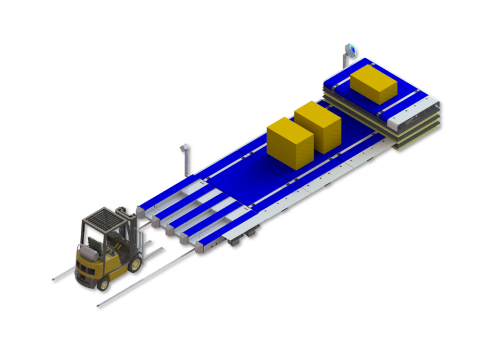

eZF™ Load FormerThis patented and patent-pending load former system semi-automatically builds bundle loads up to 96″, without pits.

|

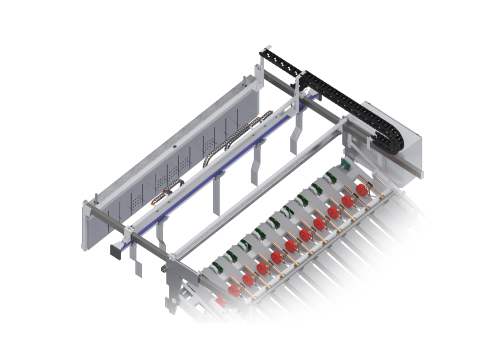

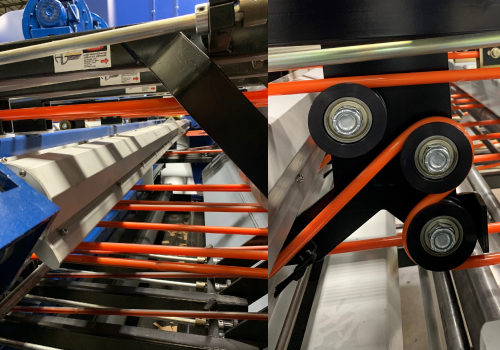

eXT™ Stacker Front EndExtreme RDC speeds, sheet control and scrap removal |

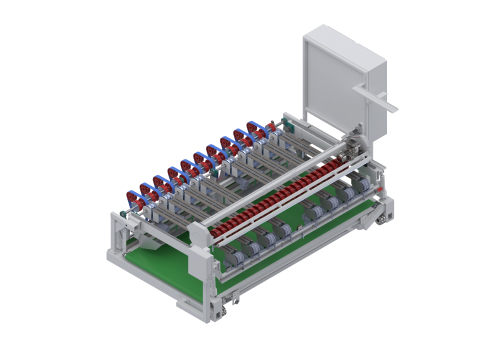

eTAMP™ Servo-Driven TampersDon’t pause production! Easily adjust all components of the hopper using the A.G. HMI. |

ePX™ Semi-Automatic Pallet InserterPart of the eSERIES™ equipment line, the ePX™ semi-automatically inserts pallets, up to 80″ x 63″

|

|

Founded with a commitment to stacker innovation, A.G. continues to pioneer new stacker solutions that move corrugated machinery operations forward.

G3™ RDC StackerThe G3™ model brings together the most popular features for high performance into one machine. |

XRI™ RDC StackerThe original A.G. Stacker module known for it’s innovative design and heavy duty construction. |

Ergonomic infeed solutions to create the most productive, safe and profitable corrugated machinery line.

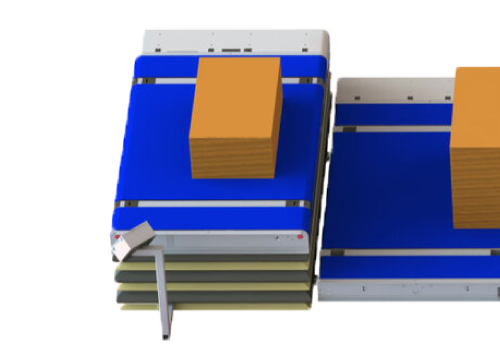

Infeed Conveyor SystemThe ergonomic infeed conveyor solution for productive corrugated converters. |

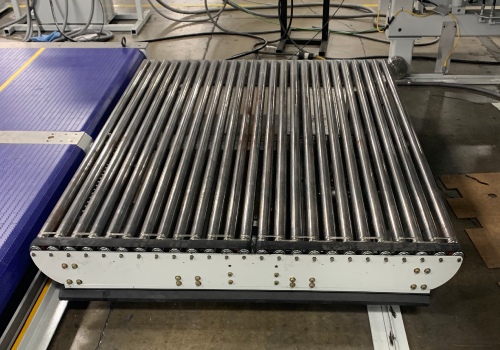

X12™ Pitless Lift Conveyor TableThe X12™ Vertical Lift Conveyor is a fully automated conveyor system, without pits! |

Innovative outfeed solutions to increase end of line efficiency.

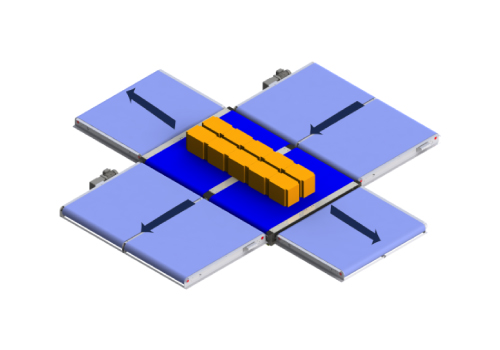

Bundle Conveyor System BCSThe fully integrated Bundle Conveyor System easily moves bundles or stacks, in any direction, downstream. |

X12™ Pitless Lift Conveyor TableThe X12™ Vertical Lift Conveyor is a fully automated conveyor system, without pits!

|

eBREAK™ Bundle BreakerCapable of a variety of bundle configurations and heights, the patent-pending eBREAK™ Bundle Breaker is a dynamic solution to improve end of line efficiency. |

eZF™ Load FormerThis patented and patent-pending load former system semi-automatically builds bundle loads up to 96″, without pits. |

Upgrade your corrugated machinery to maximize throughput, increase safety and improve stack/bundle quality.

Divert & Separate SystemPatented transfer deck engineered to automatically divert & separate corrugated sheets coming off the stacker. |

eTAMP™ Servo-Driven TampersDon’t pause production! Easily adjust all components of the hopper using the A.G. HMI.

|

eXT™ Stacker Front EndExtreme RDC speeds, sheet control and scrap removal |

|

Sample Quality Rejection SystemReceive board samples while keeping operators safe, running at full production speeds.

|

High Speed Hopper EjectorPatented backstop that integrates a second set of fingers for no feed interrupts when discharging or moving bundles. |

High Performance Layboy HPLXThe HPLX is fitted with innovative features to remove scrap and improve the quality of your finished goods. |

Intelligent Safety System ISSScan, detect, record and alert personnel in or near safety zones to ensure operator safety. |

SRX™ Scrap Release LayboyEnhanced layboy and blower design allows for increased scrap removal from the belt.

|

ePX™ Semi-Automatic Pallet InserterPart of the eSERIES™ equipment line, the ePX™ semi-automatically inserts pallets, up to 80″ x 63″

|

Let's Get Started

Discover how A.G. can increase throughput and productivity on your corrugated machinery line.