In the fast-paced world of corrugated production, efficiency and speed are paramount for maintaining a profitable operation. To increase production, some converters have invested in a high performance rotary die cutter only to find they are still not reaching the rated speeds offered by these OEM’s. Often, the delivery end equipment simply can’t keep up with the new system or is restrictive with regards to finished product mix flexibility. Though your new RDC can run faster, it is limited by the back end and you may have to settle for reduced speeds of your star asset to ensure that finished goods make it to the end of the line and out the door with quality maintained.

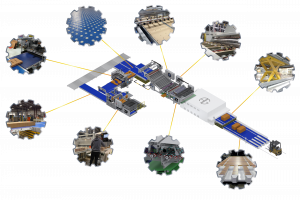

A.G. is proud to manufacture cutting-edge material handling solutions designed to meet and exceed the speeds of today and in the future. Capable of running up to 13,500 kph+, our G3 RDC Stacker is equipped with multiple patented and patent pending systems designed to increase production efficiency. Optimized for stacks or bundles, in a single machine, A.G. has engineered a modular full line system, including the eBreak Bundle Breaker, eZF Load Former, Bundle Conveyor System and more – fully integrated for maximum thoughput.

In this blog, we’ll explore how you can increase rotary die cutter speeds through investments in post-RDC machinery and innovation upgrades with A.G.

High-Performance Layboy Section (HPLX): Elevating Die Cutter Speeds

SRX Scrap Release Layboy: Precision Scrap Removal

Full Stacking Mode with DSS & eTamp Combination

The DSS and eTamp are engineered for separating a stream of sheets into full stacks with auto set-up for diverting, dividing and tamping. This equipment combination enables top productivity for full stacking operations. View our blog on choosing the right equipment for stacks or bundles to learn more.

Divert & Separate System (DSS): Streamlining Corrugated Sheet Handling

The Divert & Separate System (DSS) is a game-changer in corrugated sheet handling optimization. Positioned behind the layboy, this patented transfer deck is perfect for the plant that runs numerous jobs that are 2-4 outs with a high repeat rate. Equipped with eight arms, The DSS automatically diverts, separates, and neatly streams corrugated sheets coming off the stacker. Adjustments can be made with a simple swipe on the HMI, enabling automatic diversion and separation at full production speeds. The DSS also facilitates order recipe recall, completing the flexibility with your production process.

eTAMP™ Servo-Driven Tampers: Automation for Efficient Stacking

View our blog on choosing the right equipment for stacks or bundles to learn more.

Dynamic Bundle Breaking Mode with no Feed Interruptions

For boxmakers running orders with nicked together sheets, the eBreak bundle breaker and HSHE can quickly and easily collate and break bundles of all configurations, without any feed interruption on the RDC. Here’s how:

High Speed Hopper Ejector (HSHE): Uninterrupted Operation at High Speeds

eBreak Bundle Breaker: Dynamic Breaking in a Single Log

View our blog on choosing the right equipment for stacks or bundles to learn more.

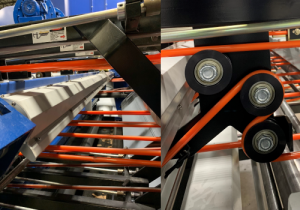

X12 Pitless Lift Conveyor Table: Continuous Operations with Safety Benefits

The X12™ Pitless Lift Conveyor Table eliminates the need to wait for discharge and stacker reset, enabling continuous stacking and feeding operations. Beyond its operational advantages, the X12™ Lift Conveyor comes with safety and financial benefits, as it requires no pits. This proven solution streamlines the infeed and outfeed process, contributing to both efficiency and worker safety.

A Full Line of Rotary Die Cutter Productivity with A.G.

A.G. has been committed to stacker innovation since 1996. With multiple patented and patented pending systems, we understand the impact your end-of-line machinery can make on overall performance and throughput. Not only the stacker, but the remaining systems such as bundle breakers, load formers, bundle conveying systems etc. can become a chokepoint in your production. In production since 2021, A.G. has released our fully electric, fully integrated new eBreak Bundle Breaker and eZF no-pit load former to offer a full line of innovation and speed.